3A Molecular Sieve

Classification:

Keyword:

- Product Description

-

3A Molecular Sieve: Specifications, Principles, and Applications

1. Specifications

| Parameter | Typical Value/Description |

|-------------------------|--------------------------|

| Pore Size | 3 Å (0.3 nm) |

| Chemical Formula | \( \text{K}_2\text{O} \cdot \text{Al}_2\text{O}_3 \cdot 2\text{SiO}_2 \cdot 4.5\text{H}_2\text{O} \) |

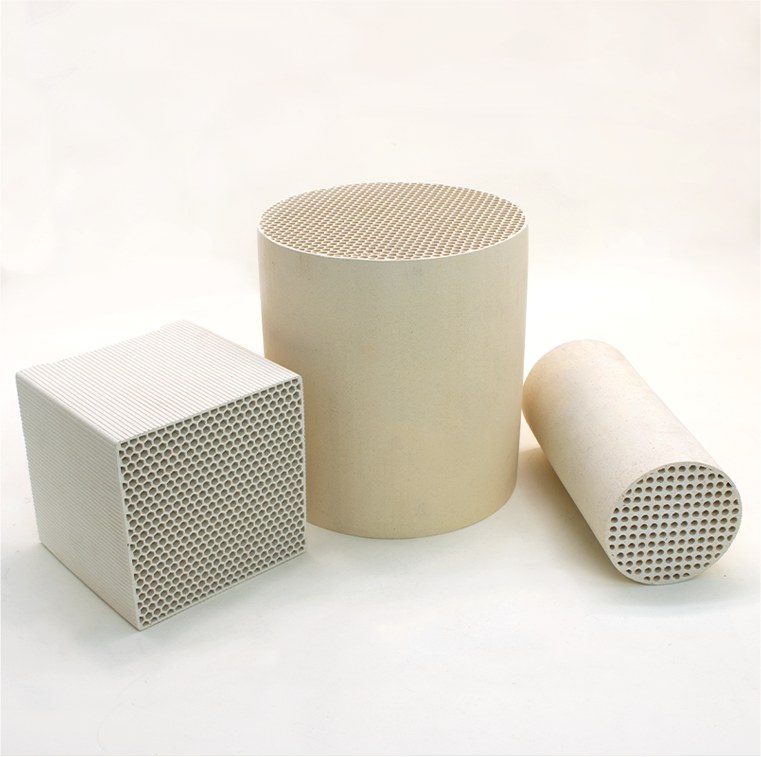

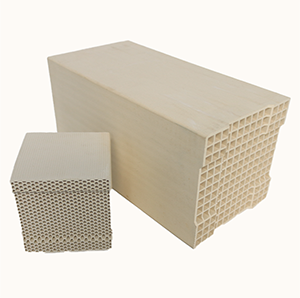

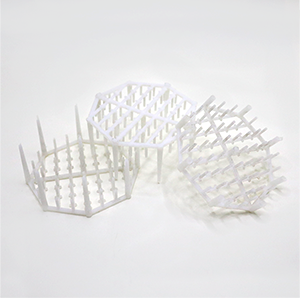

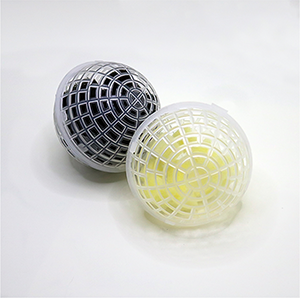

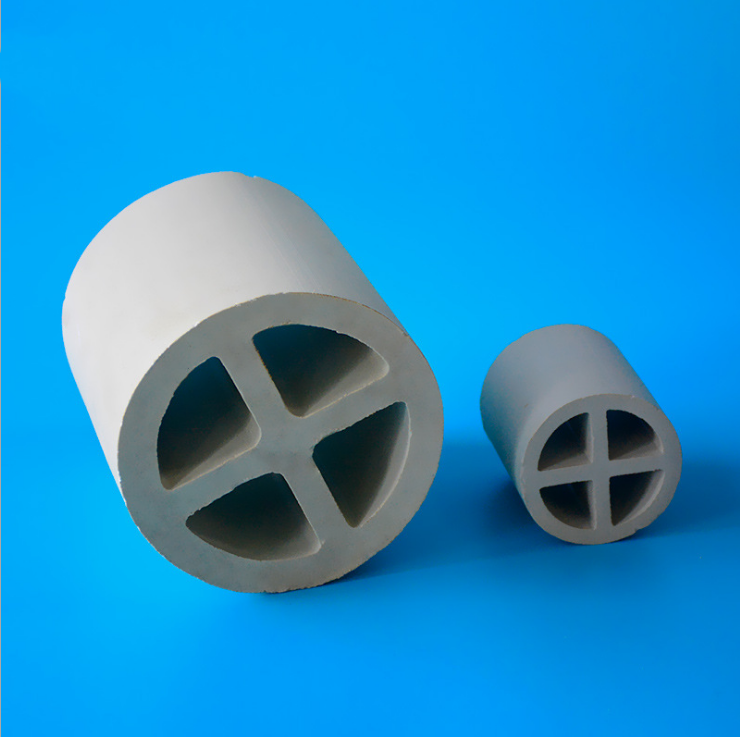

| Form | Beads (1.5–2.5 mm), Pellets (1.6–3.2 mm), Powder |

| Bulk Density | 0.60–0.75 g/cm³ |

| Crush Strength | ≥30 N/bead |

| Water Adsorption Capacity | ≥20% wt (at 25°C, 100% RH) |

| Regeneration Temperature | 200–350°C (under vacuum or inert gas) |

| pH Stability | 5–11 (stable in weak acids/bases, degraded by strong acids/alkalis) |

2. Working Principle

(1) Size-Selective Adsorption

- Adsorbs only molecules with kinetic diameter <3 Å (e.g., H₂O: 2.6 Å).

- Excludes larger molecules (e.g., CO₂: 3.3 Å, CH₄: 3.8 Å, ethanol: 4.5 Å).

(2) Ion-Exchange Modification

- Derived from 4A molecular sieve (Na⁺ form) by replacing Na⁺ with larger K⁺ ions, reducing pore size from 4 Å to 3 Å.

(3) Polar Adsorption Mechanism

- Negatively charged aluminosilicate framework + K⁺ cations create a strong electrostatic field, enhancing H₂O adsorption.

3. Key Applications

(1) Industrial Gas Drying

- Natural Gas/LPG Dehydration: Reduces moisture to <1 ppm, preventing pipeline corrosion and hydrate formation.

- Refrigerant (R134a) Drying: Eliminates water in air conditioning systems to avoid ice blockage.

- Insulated Glass (Double Glazing): Maintains dryness in spacer layers to prevent fogging.

(2) Petrochemical & Chemical Processing

- Ethanol Dehydration: Produces anhydrous ethanol (>99.5%) by selectively removing H₂O (excludes ethanol molecules).

- Polymer Production: Protects moisture-sensitive reactions (e.g., polyurethane synthesis).

(3) Electronics & Pharmaceuticals

- Electronics Packaging: Keeps semiconductors, lithium batteries, and ICs moisture-free.

- Pharmaceutical Stability: Prevents hygroscopic drugs (e.g., penicillin) from degradation.

(4) Energy & Sustainability

- Hydrogen Purification: Removes trace H₂O in fuel cell applications.

- Battery Electrolyte Drying: Enhances performance of lithium-ion batteries.

4. Comparison with Other Desiccants

| Desiccant Type | Advantages | Disadvantages | Best For |

|----------------|------------|--------------|----------|

| 3A Molecular Sieve | High selectivity, regenerable, long lifespan | Higher cost | Deep dehydration, polar molecule removal |

| Silica Gel | Low cost, color-indicating | Low capacity, non-regenerable | General-purpose moisture control |

| Activated Alumina | High thermal stability, mechanical strength | Less selective for H₂O | Compressed air drying |

5. Operational Guidelines

(1) Pre-Treatment

- Remove oil, aerosols, or large contaminants to avoid pore clogging.

(2) Regeneration

- Thermal Method: Heat at 250°C (under N₂ flow) for 3–4 hours.

- Vacuum Method: 150°C + vacuum for faster regeneration.

(3) Failure Indicators

- Loss of adsorption capacity (~15% drop).

- Physical damage (crushed beads, powdering).

6. FAQs

Q1: Can 3A sieve adsorb CO₂?

→ No! CO₂ (3.3 Å) is too large; use 13X sieve (10 Å) instead.

Q2: 3A vs. 4A – Which to choose?

→ 3A: Only H₂O removal. 4A: Also adsorbs CO₂, NH₃, and small hydrocarbons.

Q3: How many regeneration cycles?

→ 500+ cycles if properly regenerated (<350°C). Excessive heat destroys the structure.

Conclusion

The 3A molecular sieve is the gold standard for ultra-selective dehydration in industries requiring extreme dryness (e.g., electronics, energy, petrochemicals). Its regenerability, high capacity, and chemical stability make it irreplaceable for critical applications.

Need further customization for a specific use case? Let me know!

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn