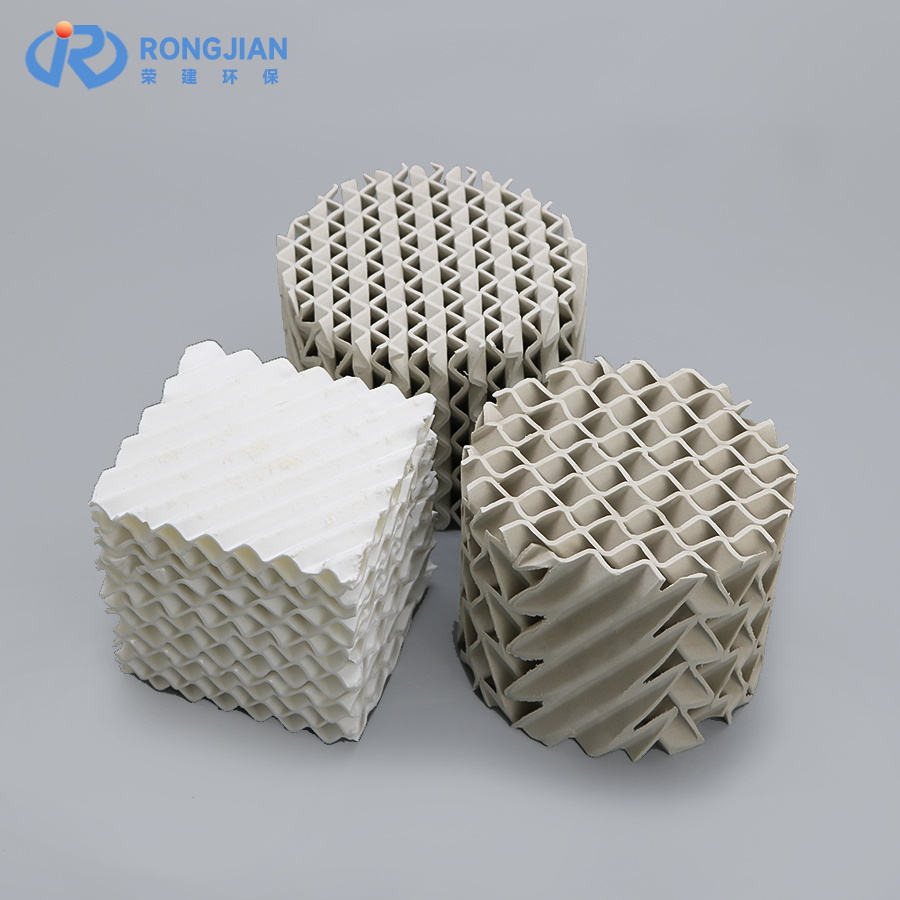

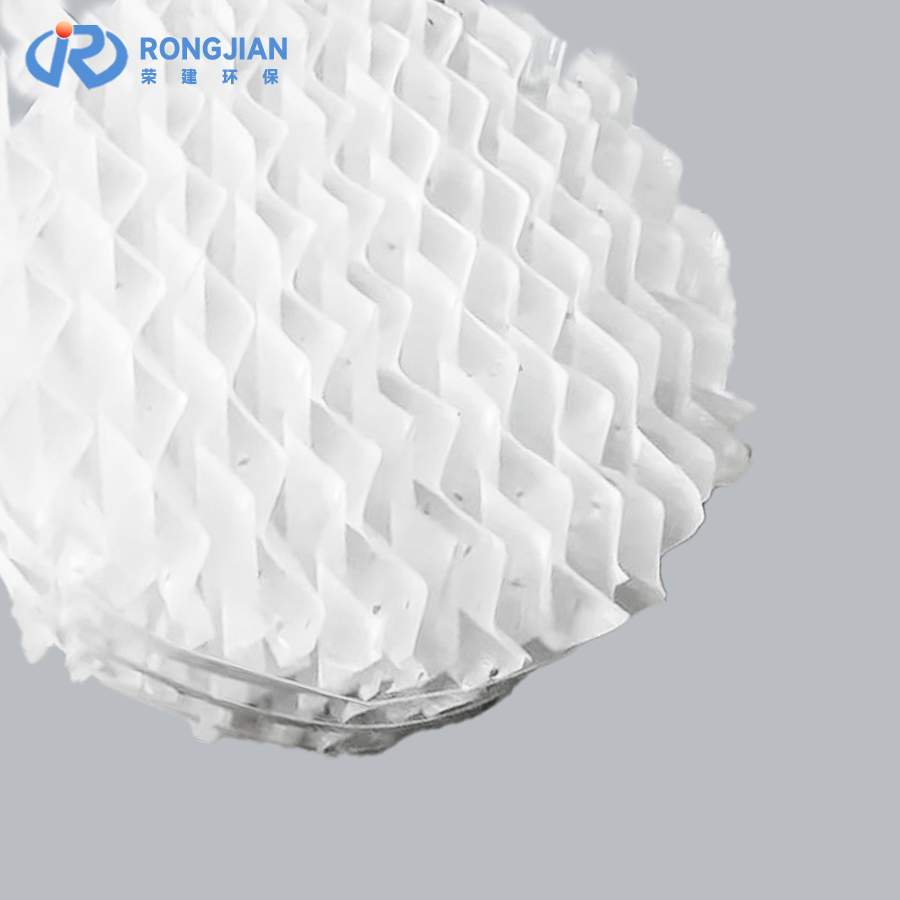

Honeycomb Ceramic Carrier

Classification:

Keyword:

- Product Description

-

Honeycomb Ceramic Carrier are high-performance ceramic structures designed for catalytic, filtration, and thermal applications in extreme temperature, corrosive, or high-pressure environments. Made from advanced ceramic materials such as cordierite, alumina (Al₂O₃), or silicon carbide (SiC), they are widely used in industries including automotive, chemical processing, environmental protection, and energy. Their unique honeycomb structure provides a large surface area, excellent thermal stability, and efficient gas flow distribution, making them ideal for applications such as catalytic converters, particulate filters, and heat exchangers.

Application fields:

1. Environmental Protection and Waste Gas Treatment

• Automobile Exhaust Purification: As the core catalyst carrier for three-way catalytic converters (TWC), selective catalytic reduction (SCR) denitrification, and particulate filters (DPF/GPF).

• Industrial Waste Gas Treatment: Used as the catalyst carrier for VOCs catalytic combustion, and the efficient heat storage body in regenerative thermal oxidizers (RTO).

2. Industrial Filtration

• High-Temperature Flue Gas Treatment: Used in industries such as waste incineration and metallurgy as catalytic filters to achieve integrated dust removal and harmful gas degradation.

• Molten Metal Filtration: Used in the foundry industry to filter non-metallic impurities in aluminum, copper, iron, etc. molten liquids.

3. Chemicals and Energy

• Structured Catalytic Reactions: As the catalyst framework for key chemical reactions such as methane reforming and Fischer-Tropsch synthesis.

• Industrial Heat Storage and Energy Saving: Used as heat storage bodies in glass kilns and heating furnaces to significantly recover heat energy and improve thermal efficiency.

• Sensor Substrate: Used as the core supporting component of micro gas sensors.

Item Cordierite porous Mullite Alumina Porcelain High Alumina Porcelain Corundum Density(g/cm3) 1.8 2.0 1.9 2.2 2.5 Water Absorption(%) 23 18 20 13 12 Coefficient of Thermal Expansion

(×10-6K-1)(20~800ºC)≤3.0 ≤6.0 ≤6.3 ≤6.0 ≤8.0 Specific heat(J/KgK)(20~1000ºC) 750-900 1100-1300 850-1100 1000-1300 1300-1400 Thermal Conductivity

(W/m.k)(20~1000ºC)1.3-1.5 1.5-2.3 1.0-2.0 1.5-2.3 5~10 MAX Working Temp.(C) 1200 1400 1300 1400 1650 (MPa)

Axial crushing strengthDry 211 220 ≥11 ≥22 ≥25 Immersion 22.5 ≥2.5 ≥2.5 22.5 22.5

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn