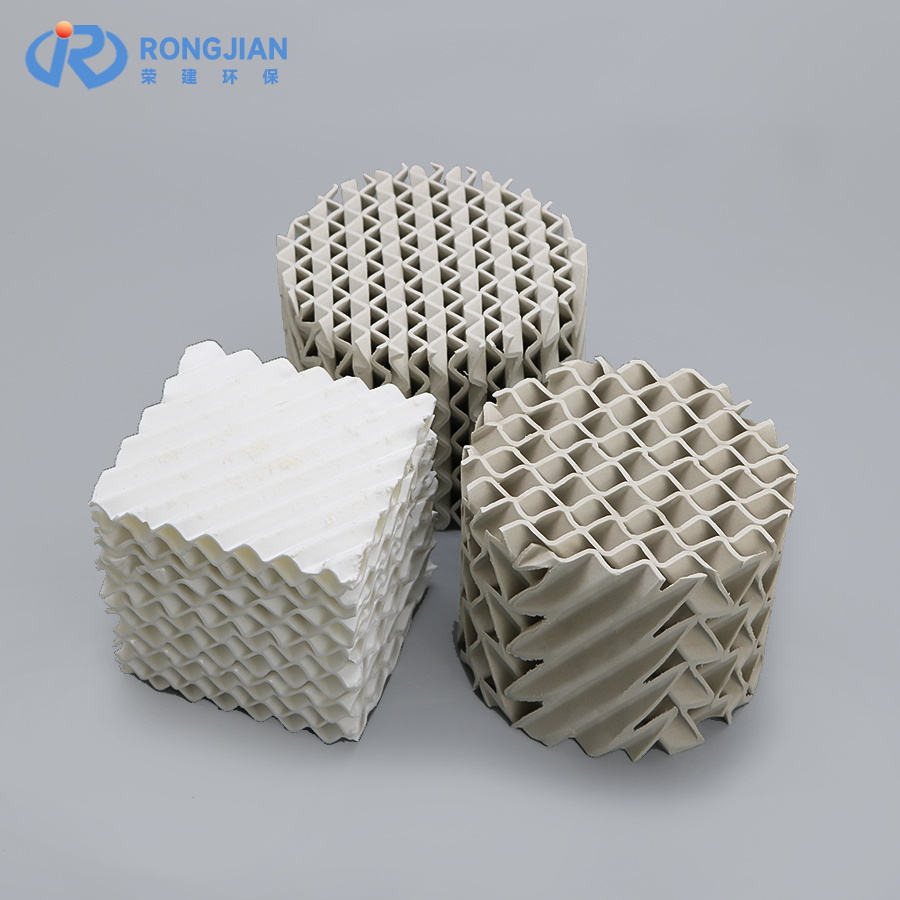

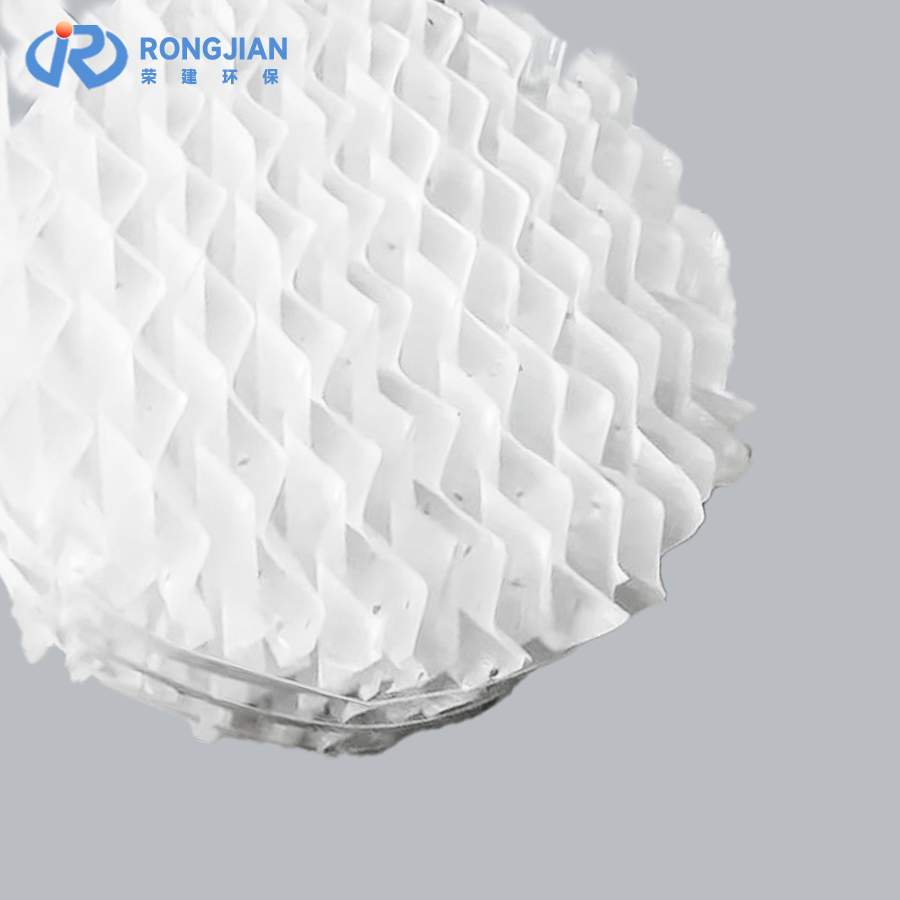

Ceramic Structured Packing

Classification:

Keyword:

- Product Description

-

Ceramic Structured Packing is a high-efficiency structured packing designed for gas-liquid and liquid-liquid mass transfer processes in extreme temperature, corrosive, or high-pressure environments. Made from advanced ceramic materials such as alumina (Al₂O₃), silicon carbide (SiC), or zirconia (ZrO₂), this packing features a corrugated surface that maximizes surface area, enhances fluid distribution, and ensures low pressure drop. Its robust design and thermal stability make it ideal for applications such as distillation, absorption, stripping, and heat exchange in chemical, petrochemical, and environmental industries.

Application fields:

1. Chemical process: Production facilities for strong acids such as sulfuric acid and nitric acid; Gas treatment systems in the chlor-alkali industry; Absorption and desorption equipment used in fertilizer production.

2. Environmental Protection Engineering: Flue gas desulfurization and denitrification equipment; Deep treatment of chemical waste gas; Acid mist recovery and purification system.

3. Metallurgical Industry: Acid production system from smelting flue gas; Metal surface treatment equipment; High-temperature gas purification equipment.

4. Special conditions: Treatment of high-temperature corrosive media; Separation process in highly oxidizing environments; Required for wear-resistant mass transfer equipment.

norm

unit

numerical value

bulk density

g/cm3

2.5

water absorption

Wt%

50.5

acid resistance

Wt%

≥99.5

heat loss

Wt%

≤5.0

Maximum operating temperature

℃

800

Crushing strength

MPa

≥130

Mohs hardness

Scale

≥7

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn