RTO Honeycomb Ceramic

Classification:

Keyword:

- Product Description

-

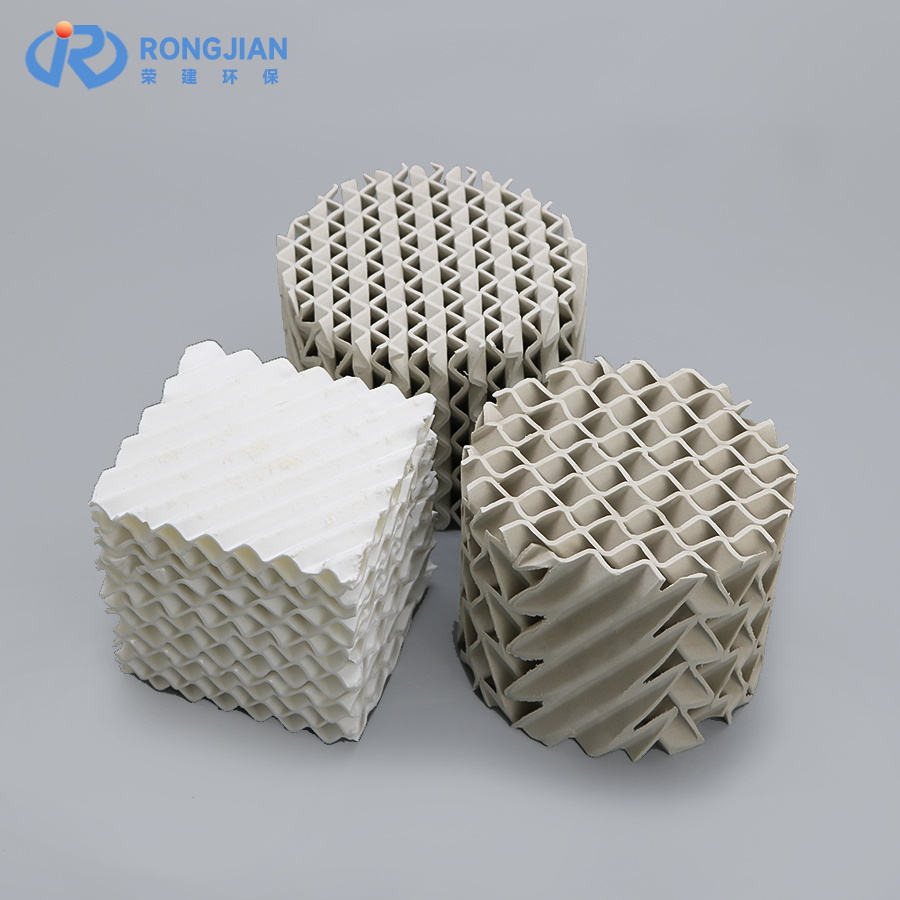

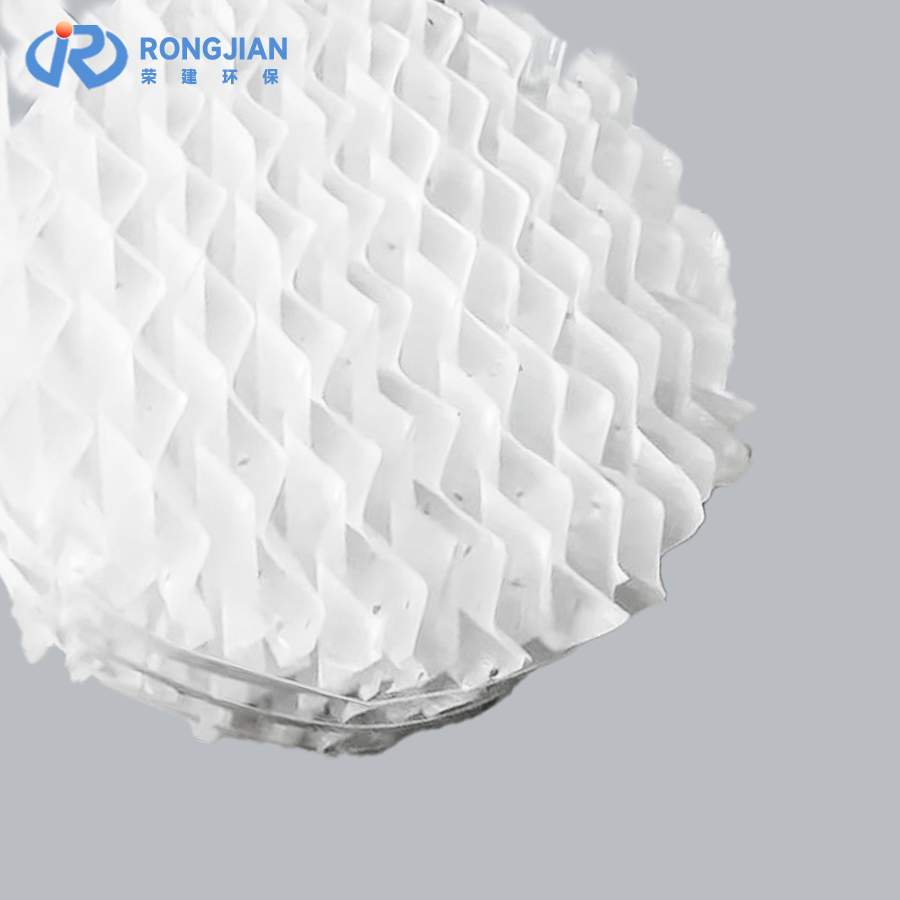

RTO Honeycomb Ceramics are specialized ceramic substrates designed for Regenerative Thermal Oxidizer (RTO) systems, which are used for volatile organic compound (VOC) abatement and air pollution control. Made from high-performance ceramic materials such as cordierite or alumina (Al₂O₃), these honeycomb structures provide a large surface area for thermal energy storage and efficient heat exchange. They are widely used in industries including chemical processing, automotive, printing, and environmental protection to efficiently destroy VOCs and hazardous air pollutants (HAPs) while minimizing energy consumption.

Core Strengths:

- Ultra-high thermal efficiency: The extremely large specific surface area ensures thorough contact with the airflow, and the heat recovery efficiency typically exceeds 95%.

- Outstanding thermal stability: Capable of withstanding frequent alternating cold and hot conditions, preventing cracking and flaking, and ensuring the structural integrity during long-term use.

- Low pressure drop: The parallel honeycomb channels allow the airflow to pass through smoothly, effectively reducing the energy consumption of the system during operation.

- Chemical resistance: Capable of withstanding the erosion of various acidic components and VOCs in the exhaust gas, with a long service life.

- High mechanical strength: The sturdy structure can withstand the pressure of the packing layer and the impact of the airflow.

Application:

• Painting and Spraying Industry: Waste gas treatment in spray painting workshops of automotive, furniture, household appliance and other industries.

• Chemical and Pharmaceutical Industry: Purification of various volatile organic compounds (VOCs) waste gas generated in production lines.

• Packaging and Printing Industry: Treatment of organic waste gas produced in printing, compounding, coating and other processes.

• Electronic Component Manufacturing: Waste gas treatment in cleaning and gluing processes during semiconductor and liquid crystal panel production.

• Food Processing Industry: Treatment of odors and organic substances generated in processes such as edible oil refining and spice manufacturing.

Item

loosened cordierite (geology)

mullite

Aluminum Porcelain

high aluminum

corundum

Density

(g/cm3)1.8

2.0

1.9

2.2

2.5

water absorption

(%)23

18

20

13

12

coefficient of thermal expansion

(×10-6K-1)(20~800℃)≤3.0

≤6.0

≤6.3

≤6.0

≤8.0

specific heat capacity

(J/KgK)(20~1000℃)750-900

1100-1300

850-1100

1000-1300

1300-1400

heat conductivity

(W/m.k)(20~1000℃)1.3-1.5

1.5-2.3

1.0-2.0

1.5-2.3

5~10

Maximum operating temperatureTemp.(C)

1200

1400

1300

1400

1650

(MPa)

Axial compressive strengthdry

211

220

≥11

≥22

≥25

immersion

22.5

≥2.5

≥2.5

22.5

22.5

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn