RCO Honeycomb Ceramic

Classification:

Keyword:

- Product Description

-

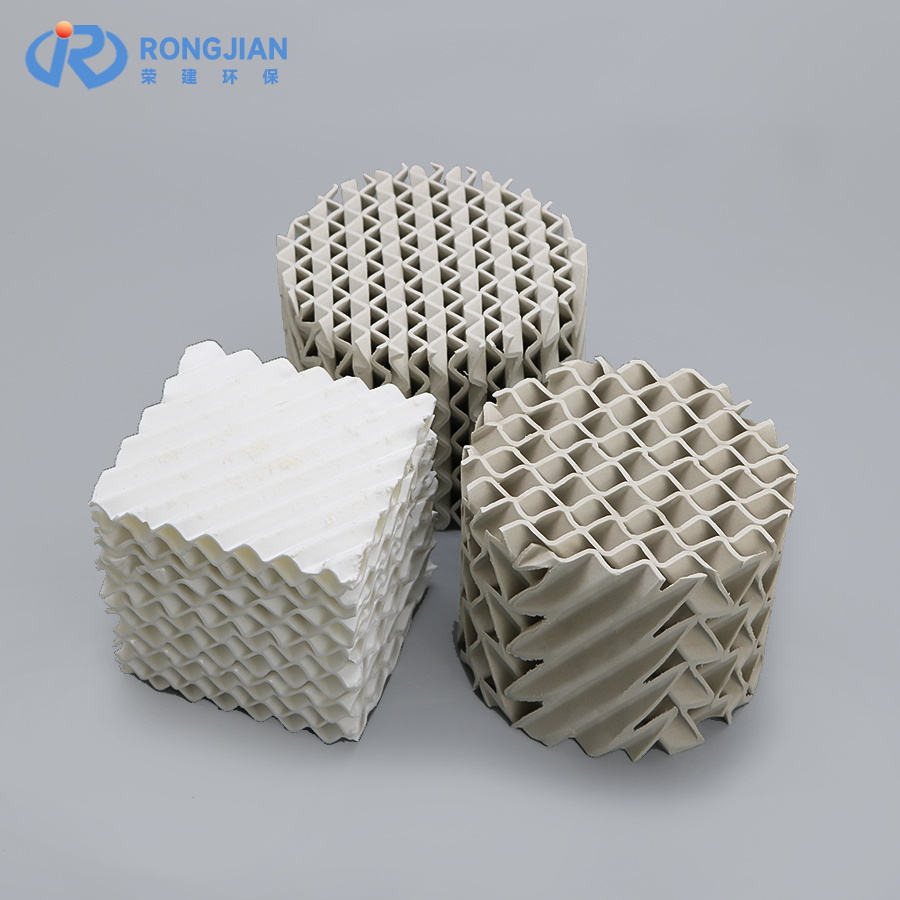

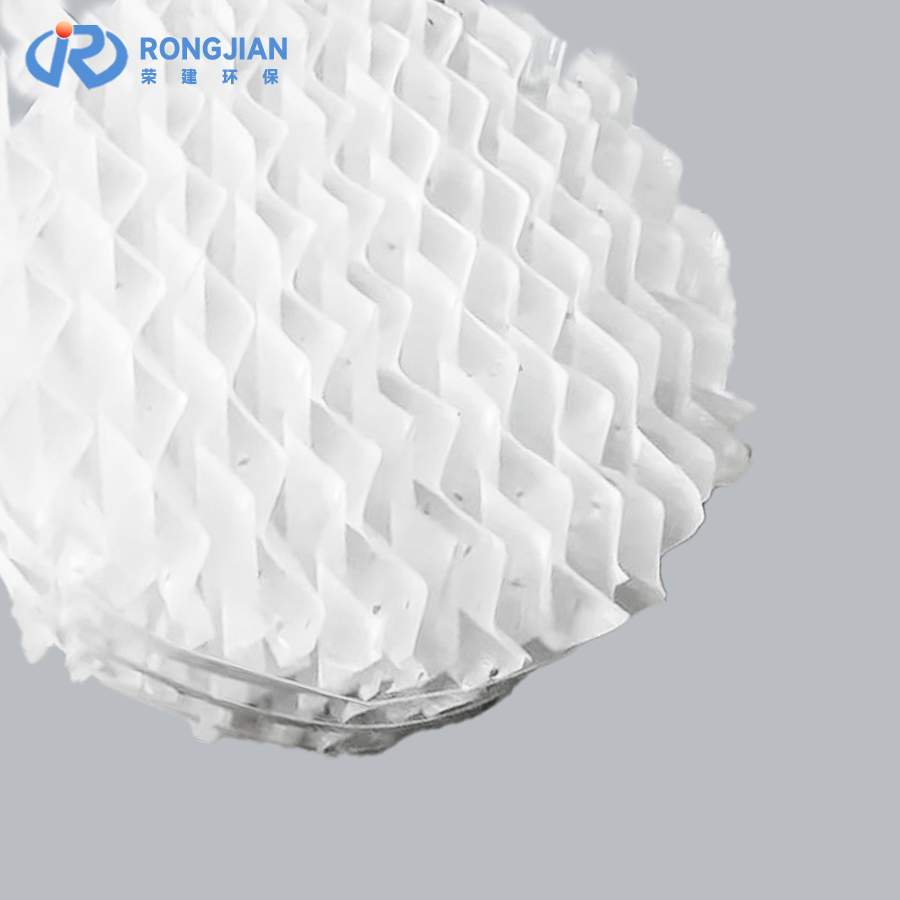

RCO Honeycomb Ceramics are advanced ceramic substrates specifically designed for Regenerative Catalytic Oxidizer (RCO) systems, which are used for volatile organic compound (VOC) abatement and air pollution control. Made from high-performance ceramic materials such as cordierite or alumina (Al₂O₃), these honeycomb structures provide a large surface area for catalytic reactions and thermal energy storage. They are widely used in industries including chemical processing, automotive, printing, and environmental protection to efficiently destroy VOCs and hazardous air pollutants (HAPs) while minimizing energy consumption.

Core advantages:

• Lower energy consumption: With the "reduction threshold" effect of the catalyst, organic waste gases can be decomposed at temperatures far lower than those required for RTO, significantly reducing fuel consumption and greatly lowering operating costs.

• Higher purification efficiency: The catalytic oxidation reaction can completely destroy VOCs, with the purification efficiency typically reaching over 98%, and it can effectively control secondary pollution.

• High heat recovery efficiency: Inheriting the heat storage advantage of RTO technology, the heat recovery efficiency can also exceed 95%, achieving remarkable energy-saving effects.

• Good safety: Due to the low operating temperature, it reduces potential safety hazards (such as NOx generation, equipment damage from high temperatures, etc.) in high-temperature environments.

Application fields

• Chemical and fine chemical industries: Dealing with complex VOCs waste gases containing halogens, sulfur and other elements. The low-temperature oxidation of RCO can reduce the generation of acidic gases.

• Packaging printing and coating industry: Handling organic solvent waste gases such as esters, alcohols and ketones produced during printing, compounding and coating processes.

• Industrial coating industry: Waste gases from spray drying workshops of automobiles, furniture and metal products, especially suitable for production lines that are sensitive to energy consumption.

• Pharmaceutical and pesticide industries: Dealing with various organic solvents that are volatilized during production, achieving efficient and thorough purification.

• Food processing industry: Removing odors and organic pollutants generated during the refining of edible oil and the manufacture of flavor essences.

Item

loosened cordierite (geology)

mullite

Aluminum Porcelain

high aluminum

corundum

Density

(g/cm3)1.8

2.0

1.9

2.2

2.5

water absorption

(%)23

18

20

13

12

coefficient of thermal expansion

(×10-6K-1)(20~800℃)≤3.0

≤6.0

≤6.3

≤6.0

≤8.0

specific heat capacity

(J/KgK)(20~1000℃)750-900

1100-1300

850-1100

1000-1300

1300-1400

heat conductivity

(W/m.k)(20~1000℃)1.3-1.5

1.5-2.3

1.0-2.0

1.5-2.3

5~10

Maximum operating temperatureTemp.(C)

1200

1400

1300

1400

1650

(MPa)

Axial compressive strengthdry

211

220

≥11

≥22

≥25

immersion

22.5

≥2.5

≥2.5

22.5

22.5

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn