Alumina grinding ball

Classification:

Keyword:

- Product Description

-

Alumina grinding balls, also known as alumina ceramic balls, are spherical grinding media made from high-quality alumina (Al₂O₃) as the main raw material. They are produced through processes such as batching, grinding, powdering, shaping, and high-temperature sintering. Due to their excellent properties such as high hardness, high density, wear resistance, and corrosion resistance, they have become crucial consumables in many industries' grinding and dispersion processes.

Features and Advantages:

- High hardness and high wear resistance: The Mohs hardness reaches up to level 9, with extremely low wear. It can reduce the contamination of materials and significantly extend the service life.

- High density and high strength: High volume density, high compressive strength, ensuring that it won't break easily during high-speed operation, and capable of providing stronger impact force, thereby enhancing the grinding efficiency.

- Excellent corrosion resistance: Strong resistance to acids, alkalis and other chemical substances, suitable for harsh environments such as wet grinding, ensuring the purity of the materials.

- Low operating cost: Although the unit price is relatively high, the extremely low wear rate and long service life significantly reduce the overall usage cost and replacement frequency.

- Energy conservation and consumption reduction: High density and high efficiency help shorten the grinding time, or use smaller ball diameters at the same fineness, thereby reducing the energy consumption of the equipment.

- Comprehensive specifications: We offer a wide range of diameters from the micrometer level (such as 0.5mm) to several tens of millimeters (such as 70mm), meeting the requirements of various devices and processes.

Application fields:

- Ceramic industry: Grinding ceramic glazes and raw materials for ceramic bodies (such as quartz, feldspar, etc.).

- Building materials industry: Grinding cement raw materials, slag micropowder, etc.

- Coatings, paints and inks industry: In equipment such as sanding machines, pigments and fillers are dispersed into liquids.

- Electronic materials industry: Grinding high-end electronic materials such as piezoelectric ceramics, magnetic materials, and fluorescent powders.

- Mining and Metal Smelting: During the beneficiation process, the metal ores are ground to facilitate the subsequent chemical leaching.

- Chemical and pesticide industry: Grinding chemical raw materials, dyes, pesticides, etc.

- Pharmaceutical and food industry: Grinding raw materials for medicines, food additives, etc.

Intems

Grinding ball parameters

Al₂O₃ (%)

≥75

≥80

≥90

≥92

≥95

SiO₂ (%)

<20

<16

<7

<5

<3

Fe₂O₃ (%)

<0.4

<0.2

<0.15

<0.1

<0.1

Na₂O (%)

<0.8

<0.5

<0.5

<0.4

<0.25

Bulk density (g/cm³)

3.15-3.25

≥3.30

≥3.50

≥3.63

≥3.68

Wear (‰)

<0.15

<0.12

<0.12

<0.10

<0.07

Hardness (Mohs)

8

9

9

9

9

Water absorption rate (%)

<0.02

<0.01

<0.01

<0.01

<0.01

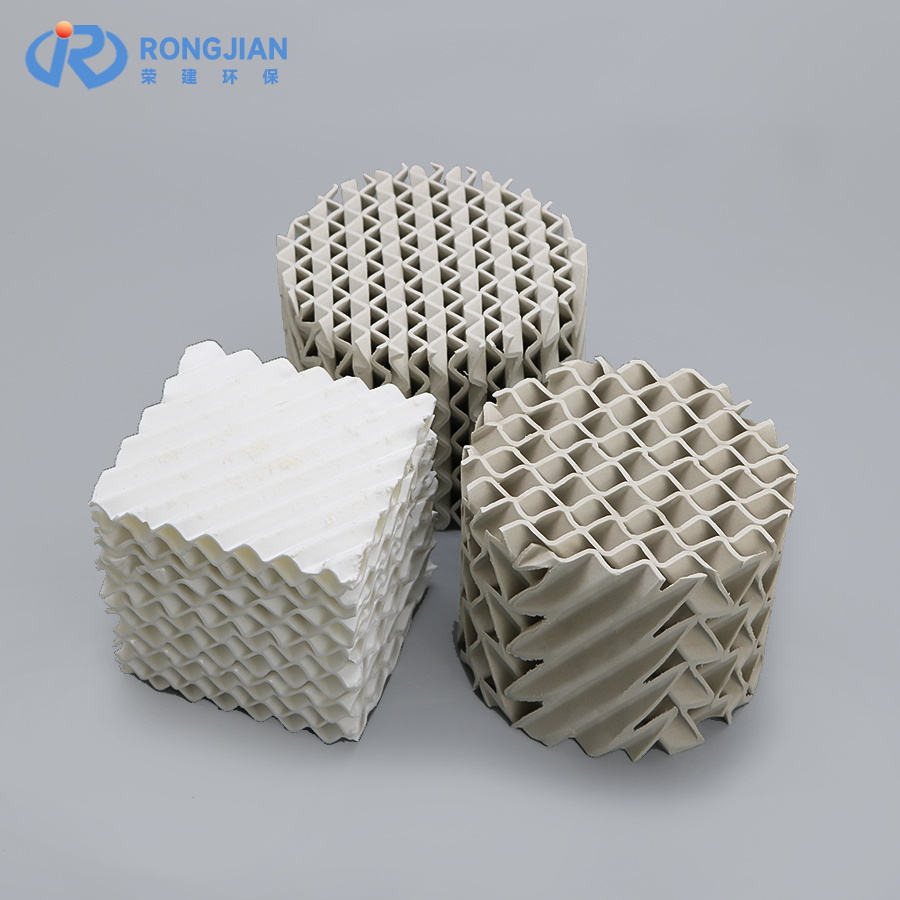

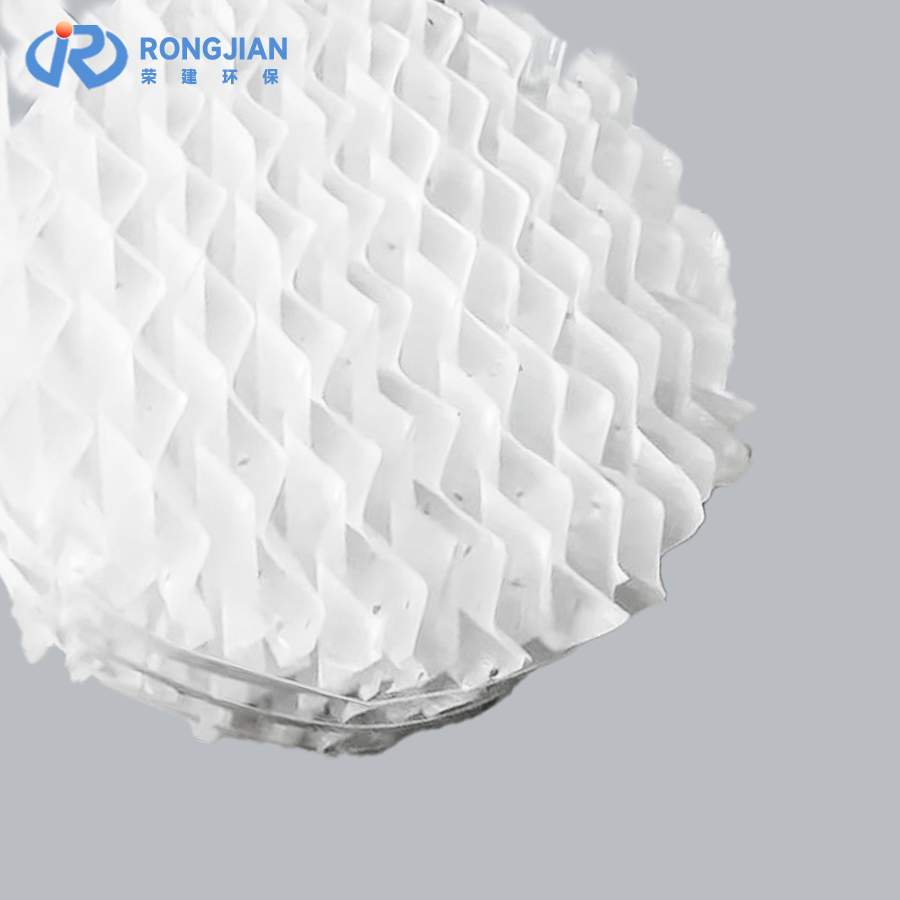

Color

grey white

White

White

White

White

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn