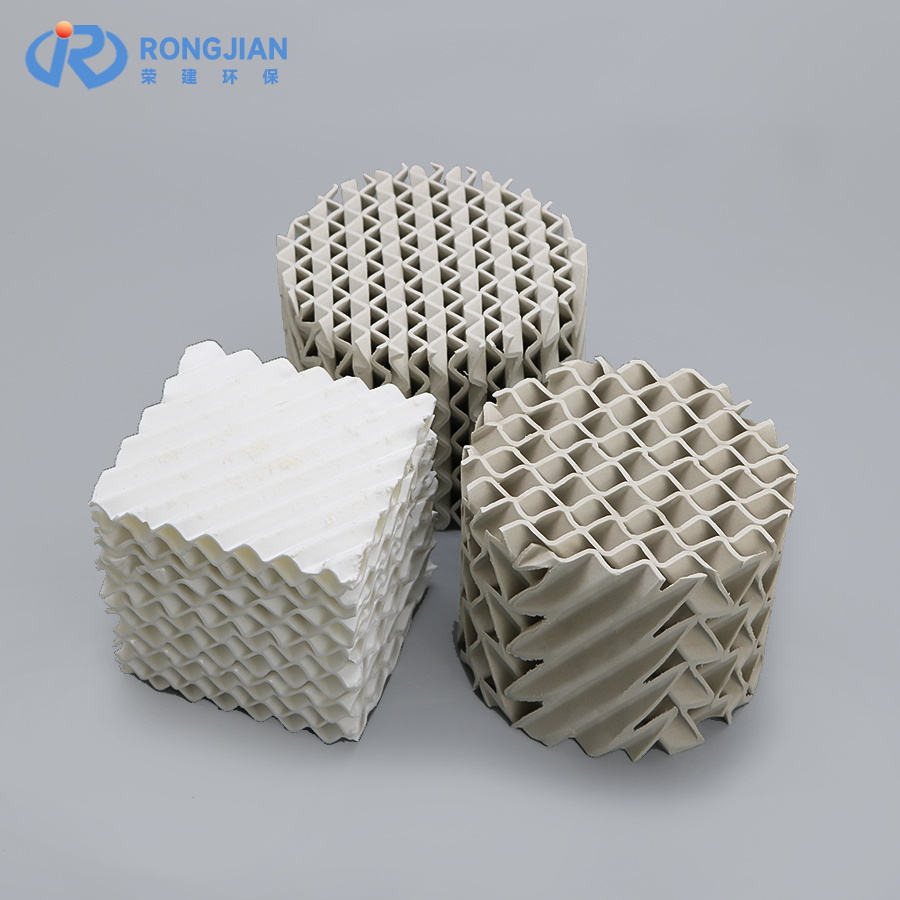

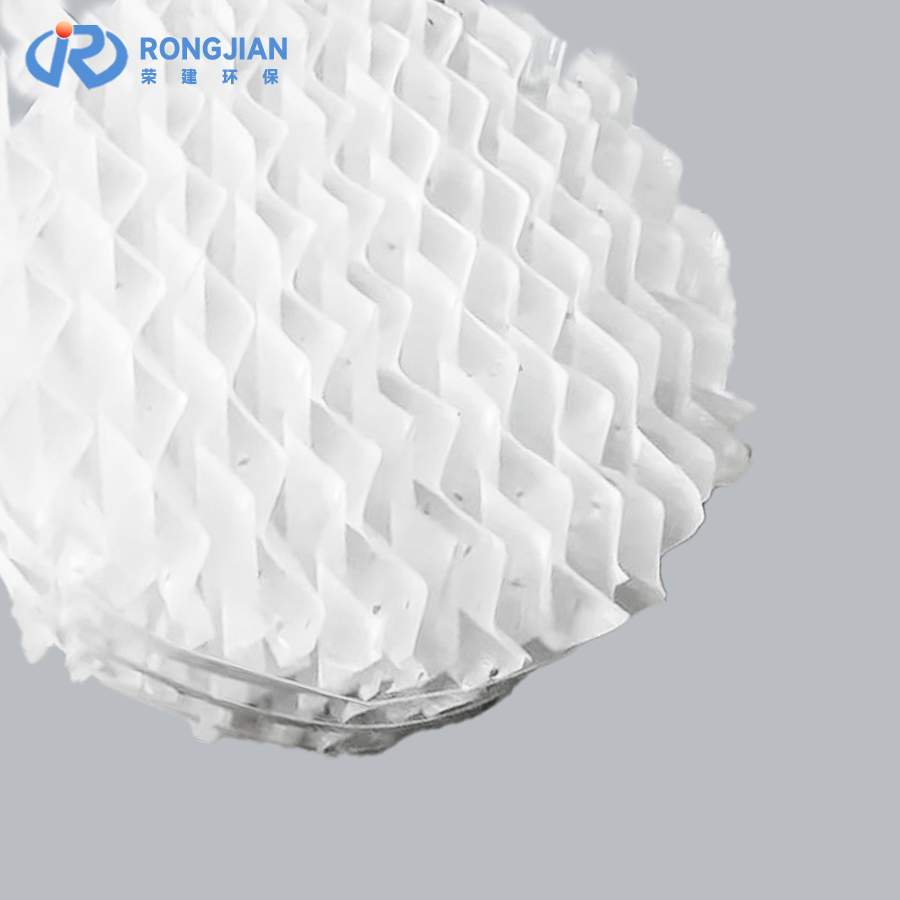

Honeycomb Ceramic Heat Accumulator

Classification:

Keyword:

- Product Description

-

The Honeycomb ceramic heat accumulator is made of high-performance ceramic materials such as corundum, mullite or silicon carbide, and is structured in a honeycomb-like pattern with numerous parallel flow channels. Its core working principle is to utilize the large specific surface area of the ceramic body to quickly absorb and store the thermal energy when the hot exhaust gas passes through, and then release the stored thermal energy when the cold air passes through, completing efficient heat exchange. This product has significant characteristics such as large heat storage capacity, high heat exchange efficiency, good thermal shock stability, and resistance to high-temperature corrosion. It is a key component for achieving energy conservation and cost reduction in industrial furnaces and exhaust gas treatment systems.

Application fields

1. The field of industrial heat treatment

Iron and steel metallurgy: Rolling steel heating furnaces, heat treatment furnaces, annealing furnaces.

Non-ferrous metals: Aluminum melting furnaces, copper processing heating equipment.

Glass industry: Glass melting furnaces, annealing ovens.

Ceramic building materials: Kilns, drying equipment.

2. Environmental Energy Field

RTO equipment: The core heat storage component in the VOCs waste gas treatment system.

Garbage incineration: Waste gas heat recovery system.

Chemical energy: Cracking furnaces, reforming furnaces, hydrogen production units.

3. Emerging Application Areas

Solar thermal power generation: Thermal energy storage system.

Industrial boiler: Waste heat recovery device.

Drying industry: Heat recovery of high-temperature drying equipment.

Item Cordierite porous Mullite Alumina Porcelain High Alumina Porcelain Corundum Density(g/cm3) 1.8 2.0 1.9 2.2 2.5 Water Absorption(%) 23 18 20 13 12 Coefficient of Thermal Expansion

(×10-6K-1)(20~800ºC)≤3.0 ≤6.0 ≤6.3 ≤6.0 ≤8.0 Specific heat(J/KgK)(20~1000ºC) 750-900 1100-1300 850-1100 1000-1300 1300-1400 Thermal Conductivity

(W/m.k)(20~1000ºC)1.3-1.5 1.5-2.3 1.0-2.0 1.5-2.3 5~10 MAX Working Temp.(C) 1200 1400 1300 1400 1650 (MPa)

Axial crushing strengthDry 211 220 ≥11 ≥22 ≥25 Immersion 22.5 ≥2.5 ≥2.5 22.5 22.5

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn