Medium Alumina Ball

Classification:

Keyword:

- Product Description

-

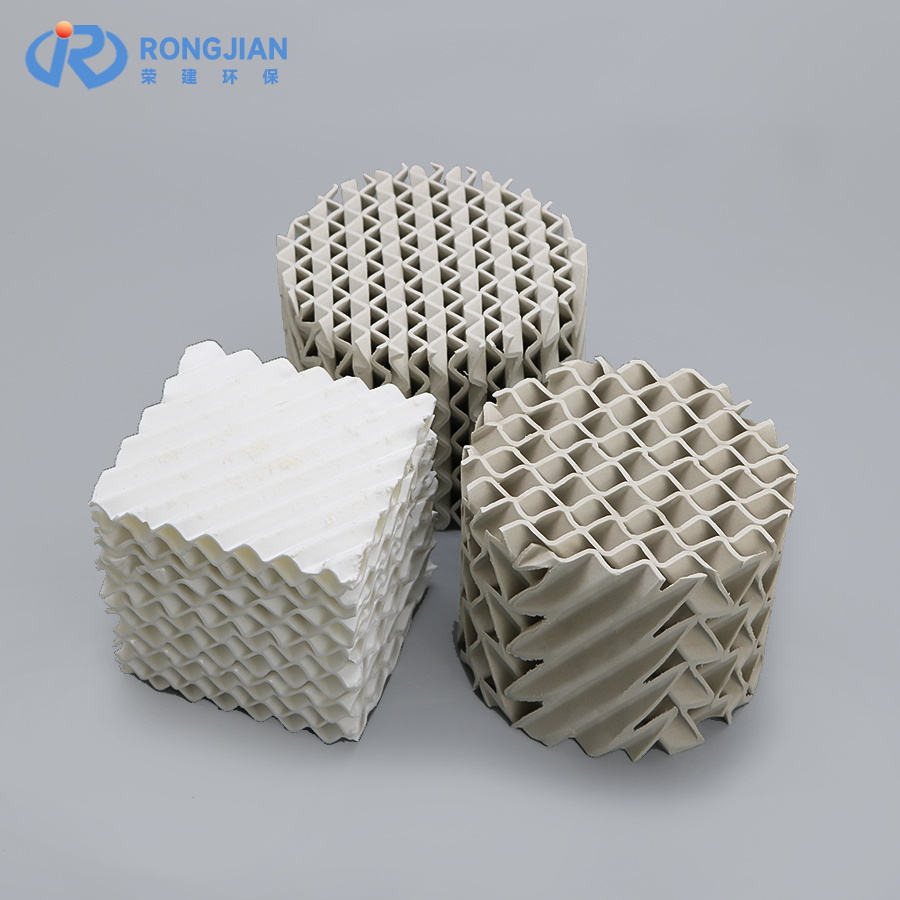

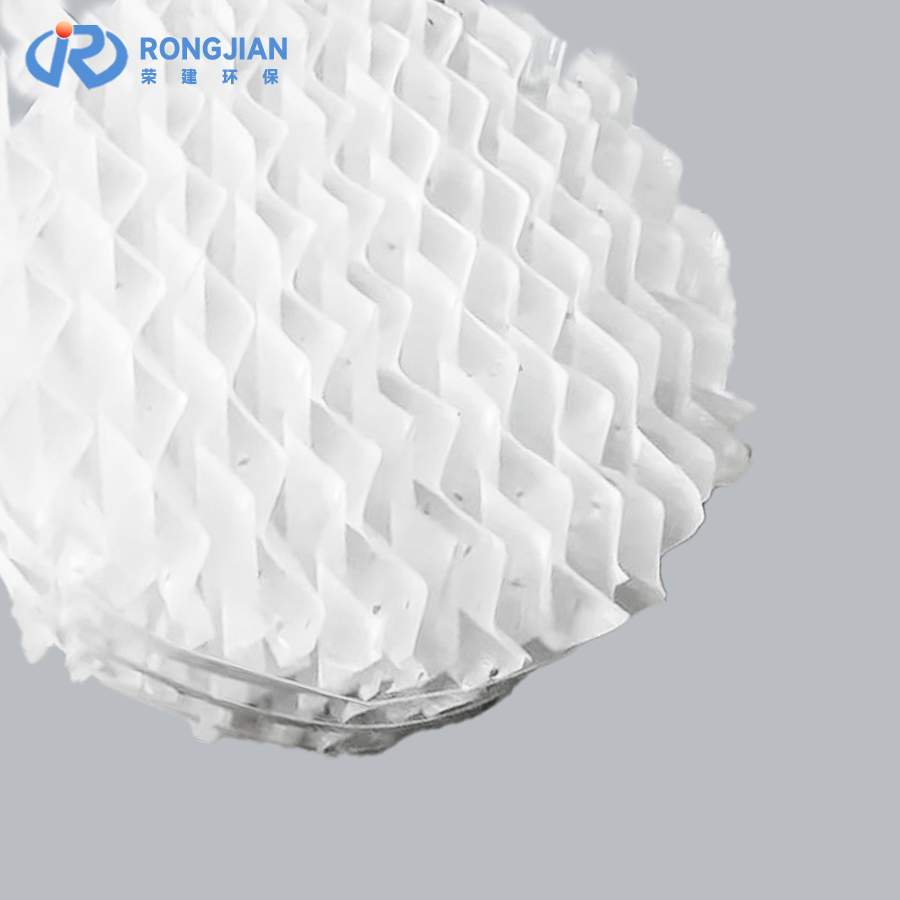

Medium-Alumina Ceramic Balls (31–75% Al₂O₃) provide a cost-effective solution for grinding and catalyst support in medium-temperature applications. They balance performance and affordability, ideal for chemical, ceramic, and mineral processing industries where ultra-high purity is unnecessary but durability is critical.

Characteristics:

1. High fire resistance: The increase in alumina content significantly enhances its fire resistance (typically > 1750°C) and the melting point, which is much higher than that of clay-based refractory materials.

2. Excellent thermal shock resistance: Due to the presence of a certain amount of mullite phase in its structure, it can better withstand sudden temperature changes and is less prone to cracking.

3. Excellent chemical resistance: It has good resistance to acidic slag and molten slag.

4. High mechanical strength: It has sufficient compressive strength at room temperature and high-temperature structural strength.

5. High cost-effectiveness: Compared to products with higher alumina content, its raw material cost and production cost have advantages, making it an economically efficient choice for many applications.Application fields

1. Ceramic building materials industry: Wet ball milling of building ceramic raw materials and glazes; Fine grinding of sanitary ceramic raw materials; Grinding of daily-use ceramic raw materials and glazes.

2. Traditional grinding sector: Processing of non-metallic minerals (such as quartz, feldspar, etc.); Dispersion grinding of chemical pigments and dyes; Processing of powder for pesticides and fertilizers.

3. Emerging application fields: Pre-treatment of environmental protection materials (ceramic granules, adsorbents); Initial grinding of raw materials for refractory materials.

4. Special process scenarios: Media for the initial grinding section of large ball mills; Protective grinding for ordinary white content requirements; General grinding media for teaching experiments.

name of product

Ordinary porcelain ball

23-30% AL203 ceramic balls

Aluminium Ceramic Balls

High Alumina Ceramic Balls

99 High Alumina Porcelain Balls

Al203+SiO2(%)

>93

>92

>93

>94

>99

Al203(%)

17-23

23-30

40-75%

85-97

99

Fe203(%)

<1

<1

<1

<1

0.2

Ca0(%)

<0.5

<1.5

<1.5

<0.5

0.2

MgO(%)

<0.5

<1.5

<0.5

<0.5

0.1

K2O+Na20(%)

<4

<4

<3.5

<4

>0.5

TiO2

<0.5

≤0.5

<0.1

<0.1

0.5

disassociate Leachable

Fe203<0.1

<0.1

<0.005

<0.001

water absorption

<0.5%

<0.5%

<1

<2

2-5

particle density

g/cm32.3-2.4

2.3-2.4

2.6-2.9

3.4

3.2-3.6

operating temperature(max)。C

980

980

1450

1580

1580

Mohs hardness

>6.5

>7

>7

>7.5

>7.5

compressive strength

KN/Particle

φ6mm

>0.5

>0.5

>0.50

>0.6

>1

φ25mm

>6.5

>6.5

>4.9

>55

>8

φ38mm

>8.9

>8.9

>5.5

>54

>8

φ50mm

>9

>9.8

>6.5

>7.8

>15

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn