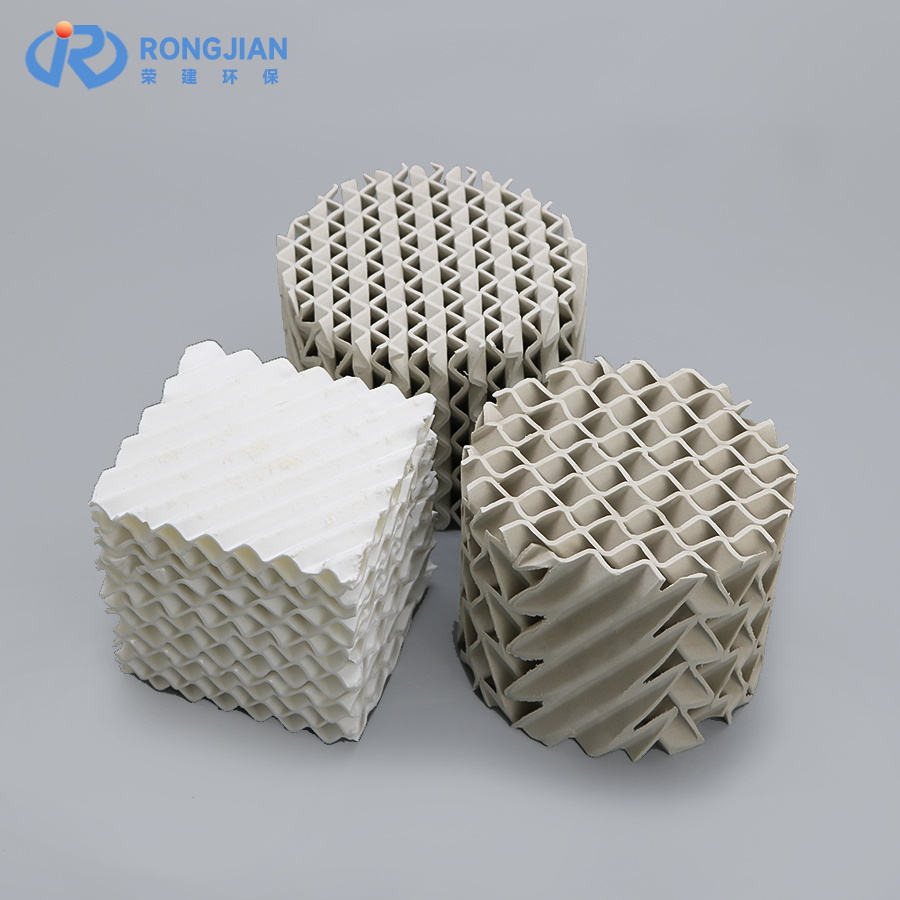

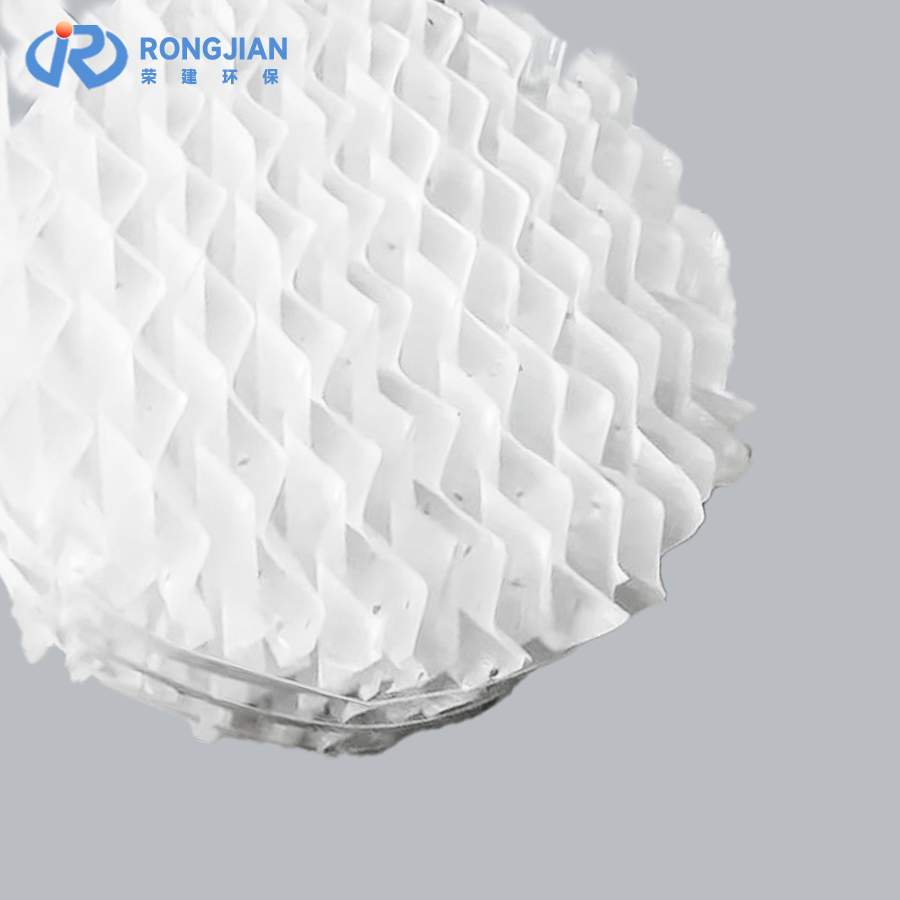

Plastic Orifice Plate Corrugated Packing

Classification:

Keyword:

- Product Description

-

Plastic Orifice Plate Corrugated Packing is a high-performance structural packing material, specifically designed for gas-liquid and liquid-liquid mass transfer processes in the chemical, petrochemical, and environmental protection industries. This packing is made of durable plastics such as PP, PVC, or PE, with a corrugated surface and evenly distributed perforations. It can effectively increase the mass transfer area, optimize fluid distribution, and significantly reduce system pressure drop. Its innovative structure ensures excellent performance in distillation, absorption, vaporization, and heat exchange processes, and is particularly suitable for industrial applications with high throughput and high separation accuracy.

Application fields:

1. Chemical and Petrochemical: Atmospheric and Vacuum Distillation Towers; Gas Absorption and Separation Towers; Solvent Recovery Facilities.

2. Environmental protection and exhaust gas treatment: Exhaust gas washing tower; Acid mist purification device; Sewage treatment stripping tower.

3. Light Industry and Medicine: Alcohol purification tower; Separation of fine chemicals; Purification of pharmaceutical intermediates.

4. Other fields: Desalination equipment; Circulating water cooling towers; Small-scale laboratory equipment.

sizes

MMspecific surface area

M2/M3Veneer pressure

Mpa/mStacked weight

kg/M3void ratio

%Theoretical plate number

Nt/(1/m)125Y

125

2*10-4

37.5

0.98

1-2.0

250Y

250

3*10-4

75

0.97

2-2.5

350Y

350

2*10-4

105

0.94

3.5-4

500Y

500

3*10-4

150

0.92

4-4.5

125X

125

1.4*10-4

37.5

0.98

0.8-1.9

250X

250

1.8*10-4

75

0.97

1.5-2

350Y

350

1.3*10-4

105

0.94

2.3-2.8

500X

500

1.8*10-4

150

0.92

2.8-3.2

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn