HTAC Heat Storage Ceramic

Classification:

Keyword:

- Product Description

-

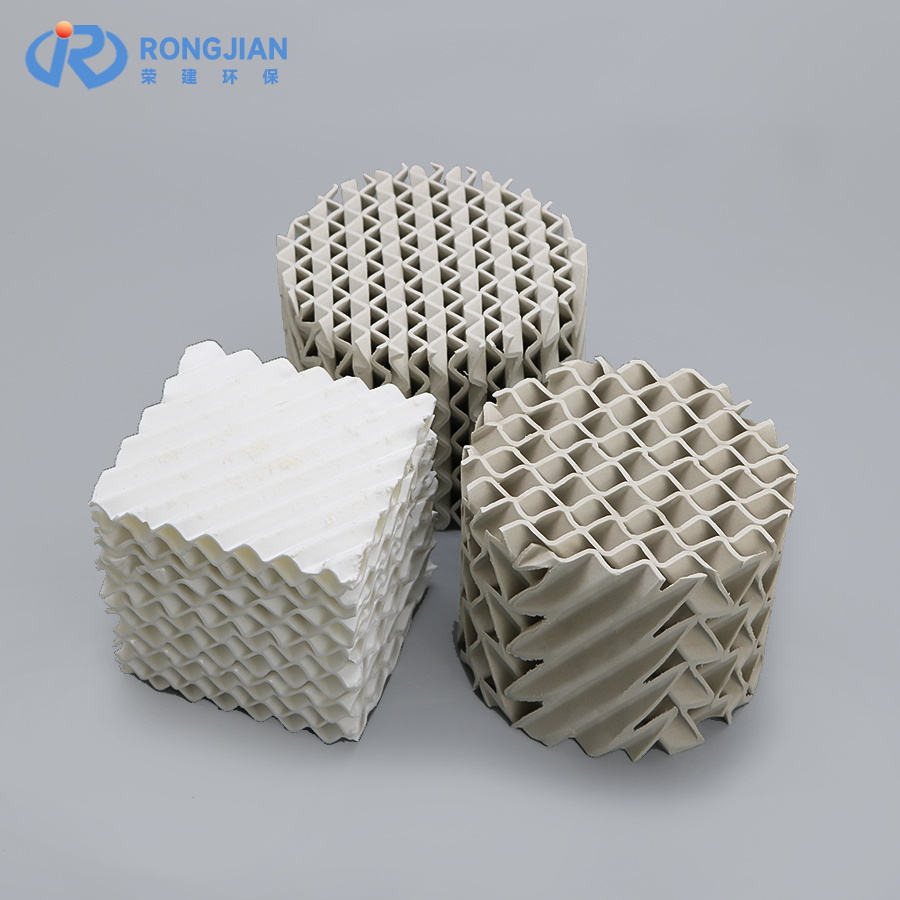

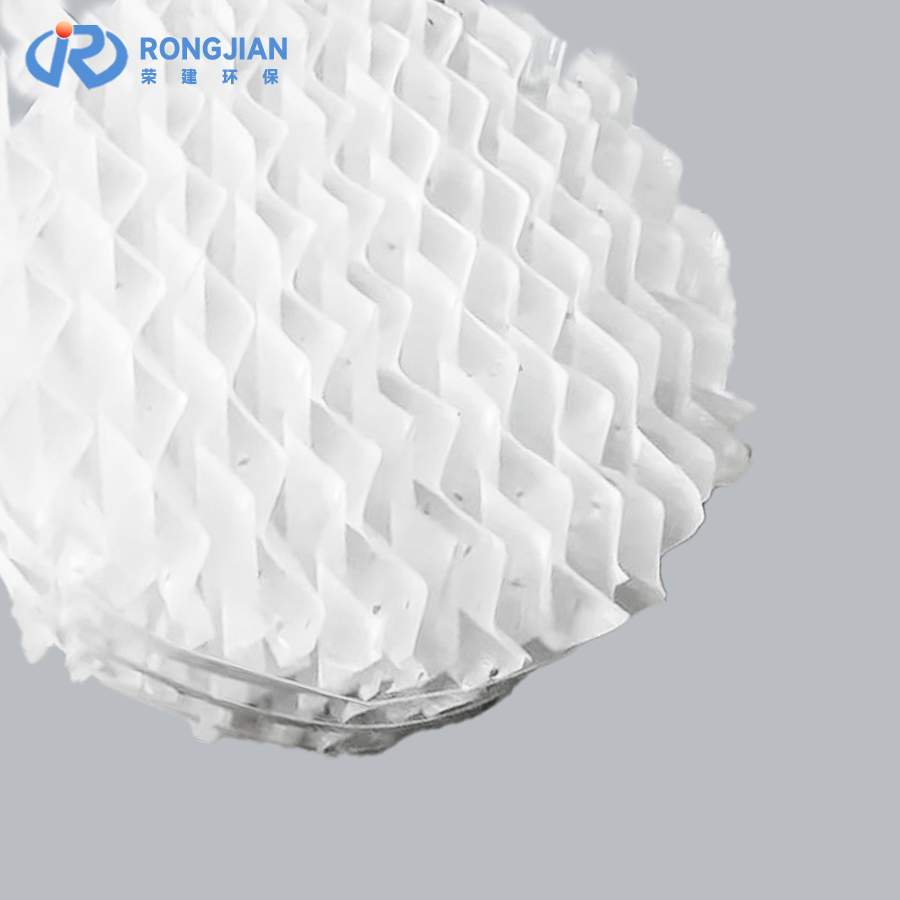

HTAC (High Temperature Air Combustion) is an advanced and highly energy-efficient combustion technology. Its core component is the HTAC heat storage ceramic. This product is specifically designed for regenerative high-temperature air combustion devices. The main body is made of high-performance honeycomb ceramic heat storage elements or heat storage ceramic balls, featuring large heat capacity, high heat exchange efficiency, and excellent thermal shock resistance.

Core Advantage:

- Ultra-high heat recovery, significant energy saving

- Stable and durable, with strong resistance to thermal shock.

- Strengthen combustion and reduce emissions

- Flexible in structure, adaptable to a wide range of situations

Main application fields:

• Metallurgical industry: Steel ladle drying equipment, heating furnaces, aluminum melting furnaces, heat treatment furnaces, forging furnaces, etc.

• Petrochemical industry: Tubular heating furnaces, cracking furnaces, reforming furnaces

• Building materials and ceramics: Glass melting kilns, ceramic roller kilns, tunnel kilns, refractory material firing kilns

• Mechanical manufacturing: Tempering furnaces, normalizing furnaces, carburizing furnaces and other heat treatment equipment

• Other fields: Waste incineration furnaces, industrial boilers, air separation system heat storage devices

Item Cordierite porous Mullite Alumina Porcelain High Alumina Porcelain Corundum Density(g/cm3) 1.8 2.0 1.9 2.2 2.5 Water Absorption(%) 23 18 20 13 12 Coefficient of Thermal Expansion

(×10-6K-1)(20~800ºC)≤3.0 ≤6.0 ≤6.3 ≤6.0 ≤8.0 Specific heat(J/KgK)(20~1000ºC) 750-900 1100-1300 850-1100 1000-1300 1300-1400 Thermal Conductivity

(W/m.k)(20~1000ºC)1.3-1.5 1.5-2.3 1.0-2.0 1.5-2.3 5~10 MAX Working Temp.(C) 1200 1400 1300 1400 1650 (MPa)

Axial crushing strengthDry 211 220 ≥11 ≥22 ≥25 Immersion 22.5 ≥2.5 ≥2.5 22.5 22.5

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn