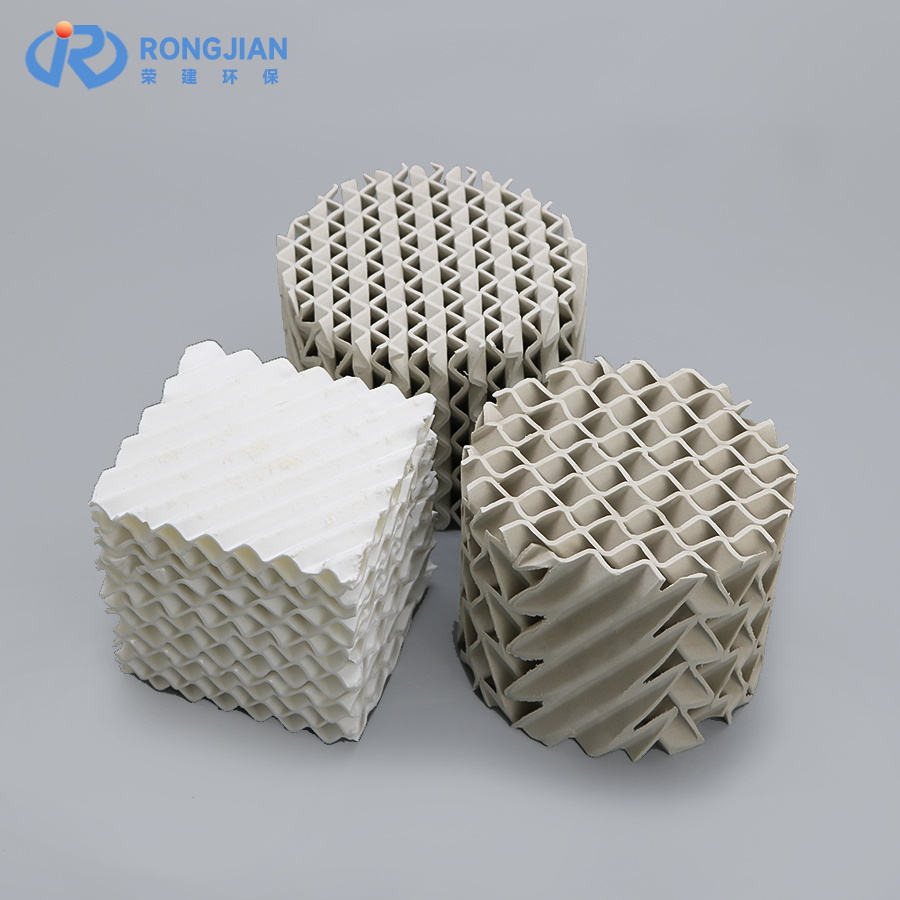

Honeycomb Ceramic Catalyst

Classification:

Keyword:

- Product Description

-

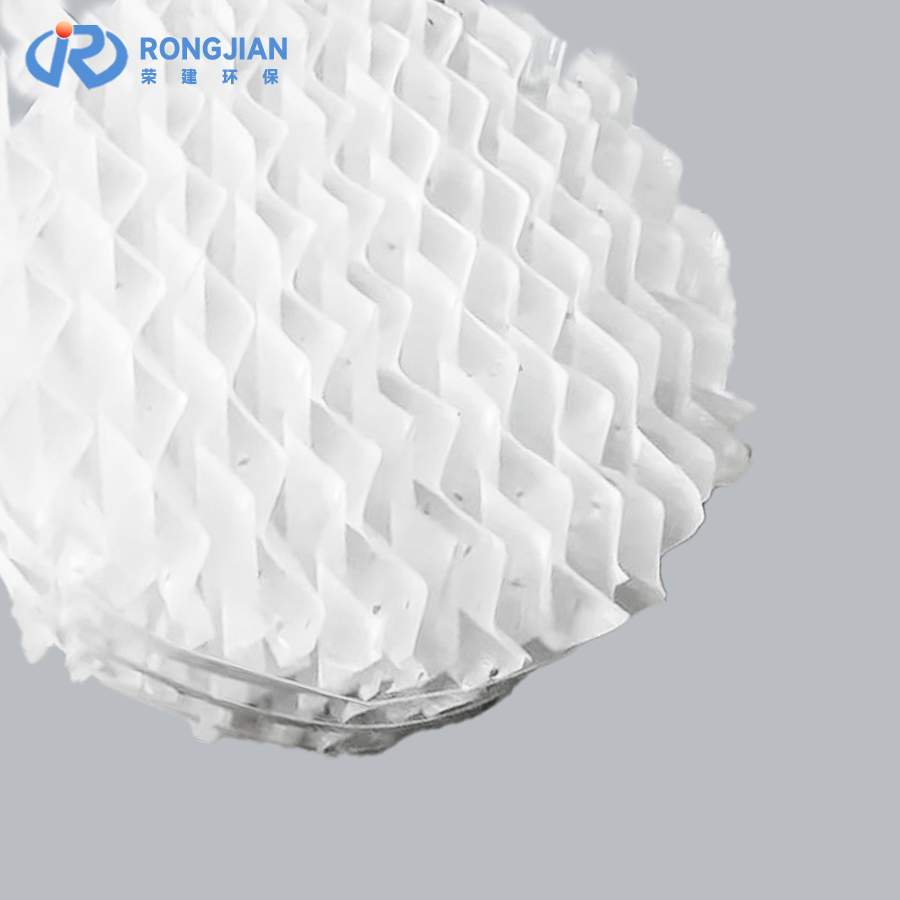

The is a highly efficient catalyst composed of high-performance honeycomb ceramics as the framework and carrier, and coated with specific catalytic materials. Its unique honeycomb structure provides a large specific surface area and extremely low gas flow resistance for gas-solid catalytic reactions, thereby enabling a highly efficient, low-energy consumption and long-life catalytic purification process.

Core Strengths:

- Extremely large specific surface area: The dense honeycomb pore walls provide extensive attachment spaces for the active components of the catalyst, ensuring that the reaction gases can fully come into contact with the catalyst.

- Low air resistance: The parallel straight-through channel design enables smooth air flow, resulting in low system back pressure and effectively reducing the energy consumption of the equipment during operation.

- Excellent thermal stability: Using materials such as cordierite and mullite, it can withstand drastic temperature changes and has strong resistance to thermal shock.

- High mechanical strength: The sturdy ceramic structure ensures that the carrier remains structurally intact even under vibration and high flow rate conditions.

- Customization flexibility: The density of holes, size, shape and catalytic coating can be precisely designed according to specific chemical reactions.

Main application fields:

• Vehicle exhaust purification: As the core component of systems such as three-way catalytic converter (TWC), diesel oxidation catalyst (DOC), particulate filter (DPF), and selective catalytic reduction (SCR), it is crucial for reducing vehicle pollutant emissions.

• Industrial waste gas treatment: Widely used in VOCs (volatile organic compounds) incineration, denitrification (SCR) of industrial boilers/kilns, and odor gas purification, etc., helping to achieve environmental protection compliance emissions.

• Chemical and petrochemical industries: In numerous chemical synthesis processes such as catalytic oxidation and selective reduction, it serves as an efficient catalyst carrier, enhancing reaction efficiency and product yield.

• Indoor air purification: Applied in air purification equipment of large buildings and factory workshops, effectively decomposing harmful gases and odors in the air.Item Cordierite porous Mullite Alumina Porcelain High Alumina Porcelain Corundum Density(g/cm3) 1.8 2.0 1.9 2.2 2.5 Water Absorption(%) 23 18 20 13 12 Coefficient of Thermal Expansion

(×10-6K-1)(20~800ºC)≤3.0 ≤6.0 ≤6.3 ≤6.0 ≤8.0 Specific heat(J/KgK)(20~1000ºC) 750-900 1100-1300 850-1100 1000-1300 1300-1400 Thermal Conductivity

(W/m.k)(20~1000ºC)1.3-1.5 1.5-2.3 1.0-2.0 1.5-2.3 5~10 MAX Working Temp.(C) 1200 1400 1300 1400 1650 (MPa)

Axial crushing strengthDry 211 220 ≥11 ≥22 ≥25 Immersion 22.5 ≥2.5 ≥2.5 22.5 22.5

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn