Refractory Ceramic Ball

Classification:

Keyword:

- Product Description

-

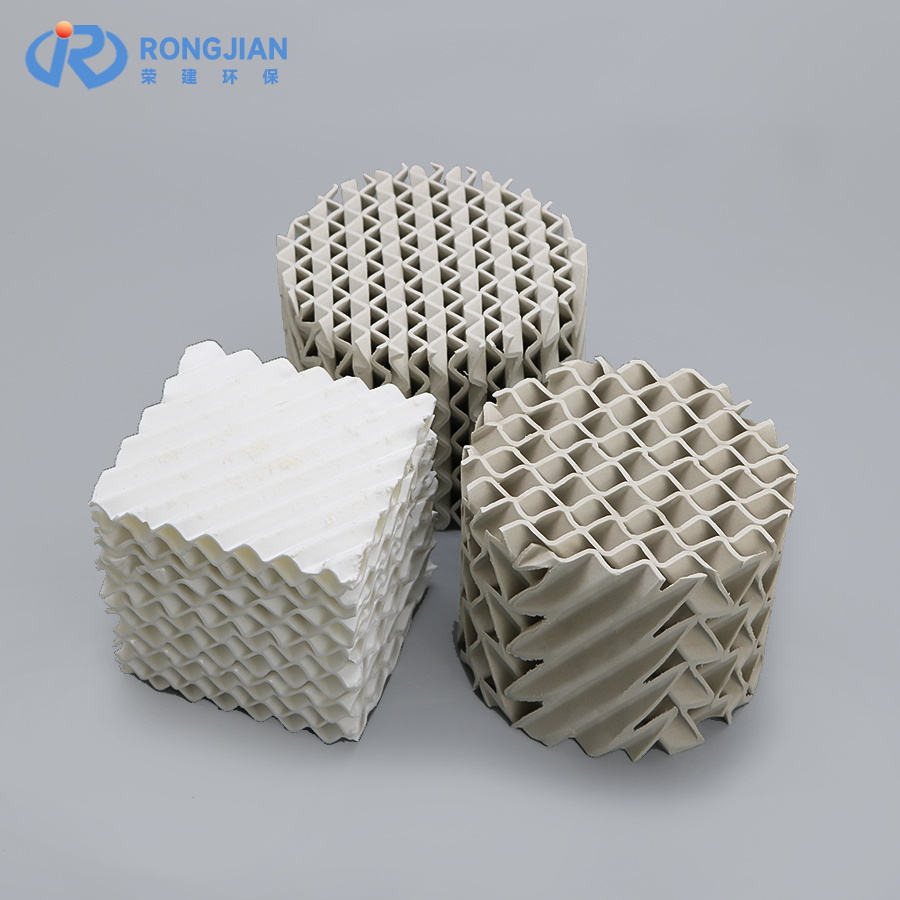

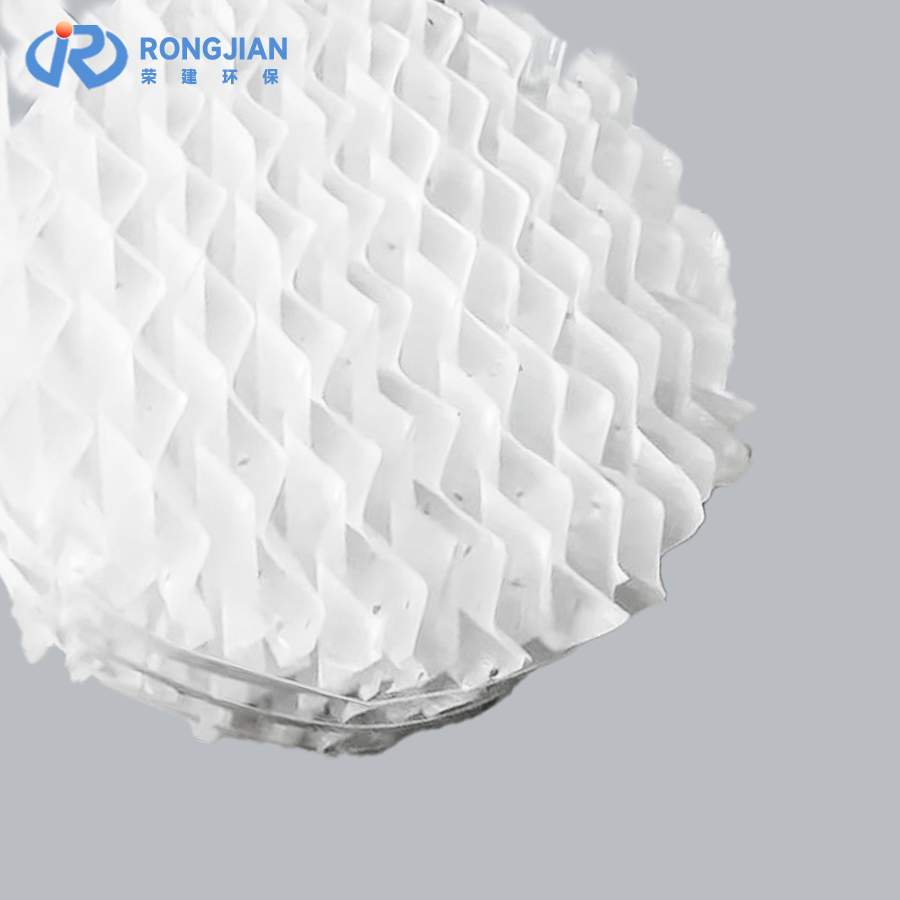

High Alumina Refractory Balls are made from industrial alumina and refractory kaolin, formed and sintered at high temperatures. Available in standard and high-alumina grades, they withstand temperatures up to 1900°C, offering exceptional mechanical strength and durability.

These inert ceramic balls are designed for extreme conditions (high temperature, corrosion, pressure) and are widely used in petrochemical, metallurgy, and energy industries. Their thermal stability and robustness make them ideal for catalyst support, heat exchange, and furnace insulation.

Key Features:

1. high temperature resistant performance, the highest heat resistant ceramic ball temperature can reach 1900 degrees;

2. high mechanical strength, long use cycle;

3. good chemical stability, no chemical reaction with the material;

4. good thermal stability, high strength.Application fields:

1. Petroleum Chemicals (Core Application) :As the supporting material and covering material for the catalyst bed layer, it is used at the bottom of reactors such as hydrogenation, cracking, and reforming, supporting the catalyst and evenly distributing the gas flow.

2. Environment and Energy :As a heat storage component, it is used in devices such as waste gas incinerators (RTO) and achieves heat energy recovery through the heat storage and release cycle, thereby reducing energy consumption.

3. Coal Chemical Industry and Natural Gas Chemical Industry :It serves as a catalyst support medium in methanol synthesis and coal-to-oil conversion facilities, maintaining the stability of the bed structure under high-temperature and high-pressure conditions.

4. Metallurgical Industry :It is used as a heat storage filler in heating furnaces and conversion furnaces, recovering the residual heat of the flue gas to preheat the air or gas, thereby improving the thermal efficiency.

5. Other industrial sectors :Used as grinding media in ball mills to grind materials; Used as a mixed filler in a static mixer to facilitate fluid mixing.

products

Refractory Ceramic Balls

Al₂O₃

≥65

Fe₂O₃

≤1.6

porosity(%)

≤24

packing density(KG/m³)

≥1386

proportion(KG/m³)

≥2350

compressive strength(KG/m³)

≥900

fire resistance(℃)

≥1800

Load softening temperature

≥1500

Reheat Shrinkage(%)

≤0.1

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn