Alumina lining brick

Classification:

Keyword:

- Product Description

-

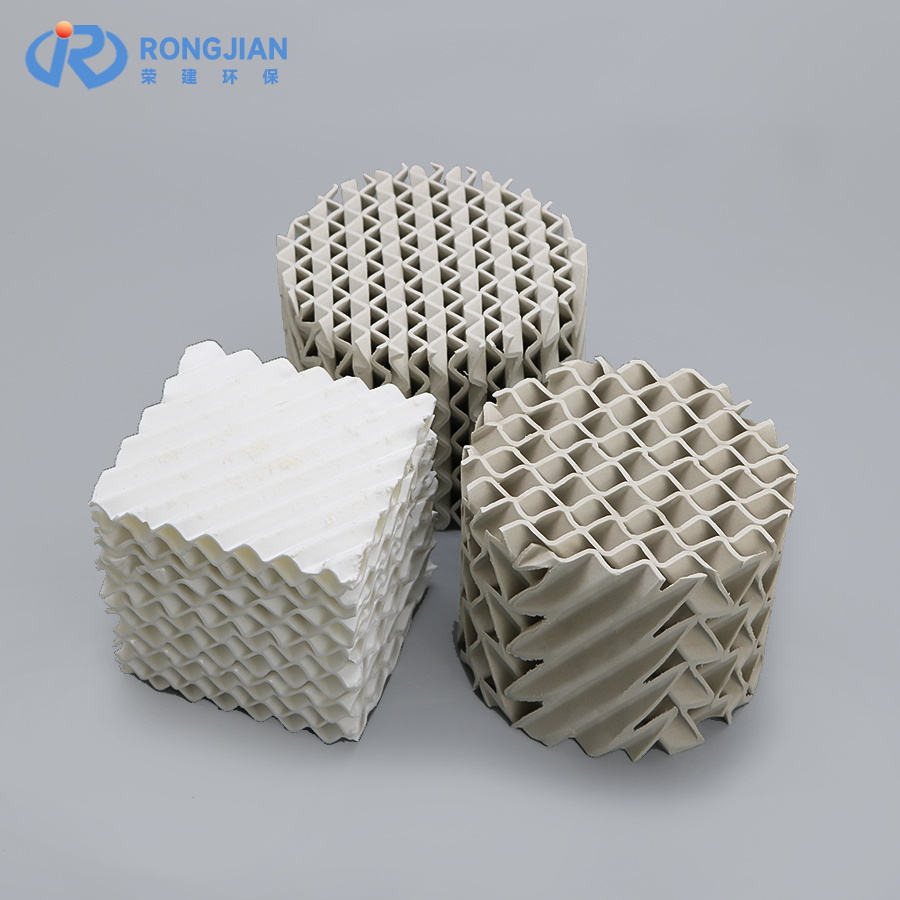

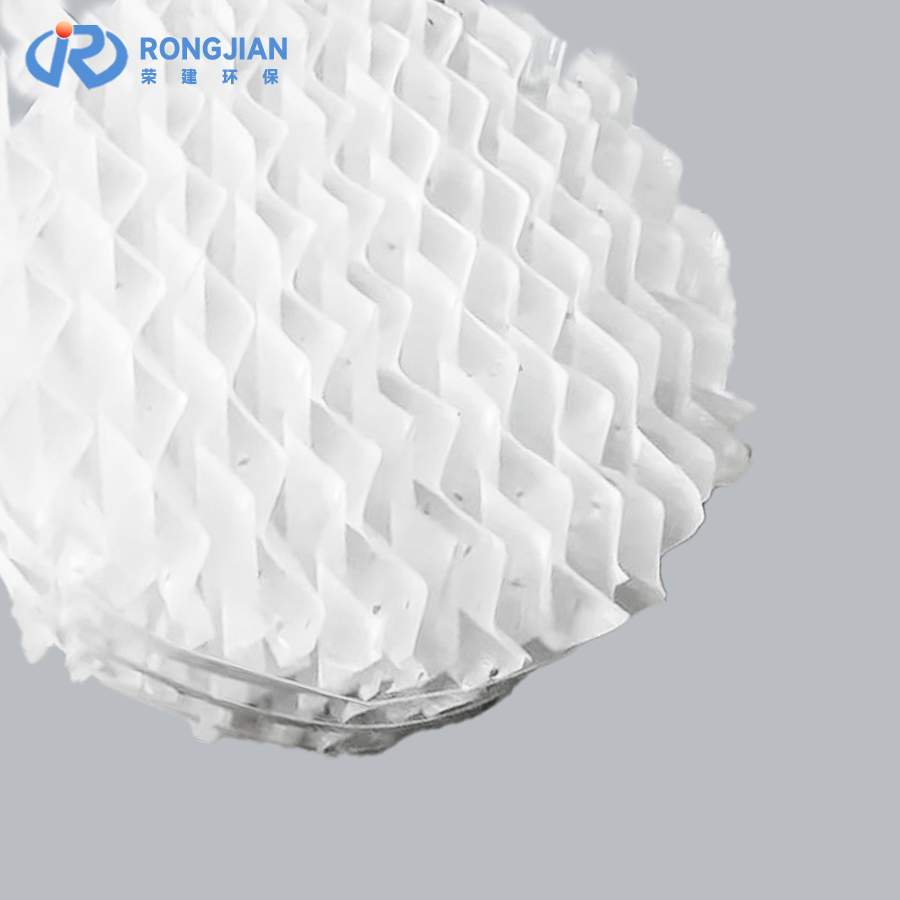

The microcrystalline wear-resistant alumina lining brick is produced using the internationally advanced hydraulic molding process, with the centrifugal granulated powder as the core raw material for refinement. The combination of advanced technology and high-quality materials enables the lining brick to have distinct features such as regular structure, dense texture, and high hardness, with particularly outstanding wear resistance.

This product can provide reliable wear protection for industrial equipment, effectively protecting equipment like ball mills from wear and significantly extending the service life of the equipment. It is a high-performance solution in the field of industrial wear protection.Application fields:

1. Building materials and cement industry: Used in key equipment such as cement rotary kilns, preheaters, and grate coolers.

2. Power and energy industry: Used in the coal-fired power plant's pulverizing and ash conveying systems.

3. Steel metallurgy industry: Applied in the air supply and dust removal systems of blast furnaces, hot blast stoves, and steel furnaces.

4. Chemicals and mining:

• Chemicals: Used for the inner lining of pneumatic conveying pipelines and fluidized bed reactors, for transporting abrasive materials.

• Mining: Used in crushing systems and ore sorting chutes, to resist severe wear of ores.

5. Environmental treatment industry: Mainly used in waste incineration furnaces and hazardous waste treatment furnaces.

Intems

Lining brick

Al₂O₃ (%)

≥75

≥80

≥92

≥95

SiO₂ (%)

<20

<16

<5

<3

Fe₂O₃ (%)

<0.4

<0.2

<0.1

<0.1

Na₂O (%)

<0.8

<0.5

<0.4

<0.25

Bulk density (g/cm³)

3.15-3.25

≥3.30

≥3.60

≥3.68

Hardness (Mohs)

8

9

9

9

Water absorption rate (%)

<0.02

<0.01

<0.01

<0.01

Color

grey white

White

White

White

Product inquiry

If you have experienced our products, you may as well tell us your true feelings. Your satisfaction is the driving force for us to move forward, and your suggestions are our precious wealth for continuous improvement.

Related Products

Customer Service Hotline

Tel/WeChat/WhatsApp:+8618079942828

E-mail/Zoom:jlee@pxrjhb.cn

Address: No. 1-269, Zone B, Industrial Park, Xiangdong District, Pingxiang City, Jiangxi Province

Customer Service

Customer Service

Website construction:300.cn